1.Product description-ceramic foundry sand

1.1Product brief introduction

1.1.1What’s ceramic foundry sand?

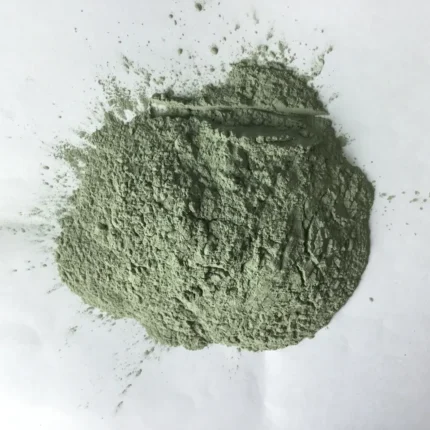

ceramic foundry sand is a kind of man-made spherical shape ceramic particles, also called as NFS ceramic foundry sand-Nice Foundry Sand,have an mean diameter in 0.053mm-3mm.

1.1.2How ceramic foundry sand made?

ceramic foundry sand was made by raw bauxite ore(Al2O3 45~90%),melting in the electric arc furnace,under the high temperature produced by the arc of the arc discharge, the raw material bauxite melting into liquid, the liquid flows out of the furnace, impose its 70 ~ 85m / s to air pressure, the liquid material with the strong wind crushing, cooled to spherical or nearly spherical shape ball, have smooth surface,the ceramsite sand ball is solid.

1.1.3What’s ceramiste sand mean for foundry industry?

ceramic foundry sand is also good substitution to Chromite sand and Zircon sand because of its lower price.At the present, ceramic foundry sand is acknowledged in the worldwide as the newest and the best ideal sand for the foundries and has a very wide feasibility of applications for the future development.

ceramic foundry sand provides a simple and efficient way in the foundry industry to improving the quality of the castings, reducing the production cost and avoiding environmental pollution so it is much better than silica sand.

1.2.ceramic foundry sand technical specifications

1.2.1 ceramic foundry sand physical specification

| shape | Spherical,round ball |

| color | Brown,black-brown,taupe |

| Refractoriness | 2050℃ |

| Liner thermal expansion | (20-1000 ℃) 6 × 10-6/℃ |

| Bulk density | 1.95 -2.05g /cm3 |

| Ture density | 3.4g /cm3 |

| thermal conductivity | (1200 ℃)5.27W/M·K |

| Size range | 6-320mesh(φ0.053-3.36mm) |

| PH value | 7-8 |

1.2.2 ceramic foundry sand chemical specification

| Compositon | Available data |

| SiO2 | 5– 15% |

| Al2O3 | 70–75% |

| Fe2O3 | 5%min |

| TiO2 | 5%min |

| MgO | 0.5%min |

| K2O | 0.5%min |

| CaO | 0.5%min |

1.2.3 Performance comparison of ceramic foundry sand,Chromite sand and Zircon Sand

| Index | cerabeads | Chromite sand | Zircon Sand |

| PH value | 7.65 | 4.56 | 8.24 |

| Bulk Density(g/cm3) | 1.95-2.05 | 2.9-3.1 | 2.6-2.7 |

| Ture density(g/cm3) | 3.4 | 4.4-4.71 | 3.9-4.8 |

| Shape | Spherical | Irregular | Irregular |

| Amount of binder

(Waterglass+CO2 hardening) |

3%—-4% | 7%—-8% | 7%—8% |

1.3 ceramic foundry sand available size

| SIZE | ASTM MESH | 10 | 16 | 20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS Range |

| Diameter in um | 1700 | 1180 | 850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| 200# | ≤2 | 15-40 | 30-55 | 15-35 | ≤3 | 15-25 | ||||||||

| 300# | ≤10 | 25-45 | 35-55 | 5-15 | ≤5 | ≤2 | 25-29 | |||||||

| 400# | ≤10 | 25-45 | 20-40 | 5-25 | ≤7 | ≤5 | 35-39 | |||||||

| 500# | ≤3 | 10-25 | 25-40 | 25-45 | 10-25 | ≤10 | ≤5 | 45-55 | ||||||

| 600# | ≤10 | 10-30 | 30-50 | 15-35 | ≤15 | ≤5 | ≤2 | ≤1 | 55-65 | |||||

| 650# | ≤8 | 10-25 | 20-45 | 20-45 | 5-20 | ≤7 | ≤2 | ≤1 | 60-70 | |||||

| 750# | ≤10 | 10-25 | 25-45 | 15-35 | ≤15 | ≤5 | ≤2 | 75-85 | ||||||

| 1000# | ≤3 | 10-35 | 35-55 | 15-35 | ≤10 | ≤5 | 95-115 | |||||||

| 1250# | ≤2 | 5-20 | 30-50 | 25-45 | 5-20 | ≤8 | 115-135 | |||||||

| 1500# | ≤5 | 5-25 | 40-60 | 25-40 | ≤15 | 155-175 | ||||||||

| 1800# | ≤5 | 35-55 | 25-45 | ≤25 | 180-210 |

1.4 Advantage of ceramiste sand

Perfect round ball shape

Perfectly round shape with higher fluidity improves fill-in efficiency while reducing the resin use level

Smooth surface of spherical shape greatly improves collapsibility after pouring

High refractoriness

Superior refractory equivalent to zircon and Chromites

Higher than silicon sand, can be used for casting various materials.

Non-stick, non-sintering on the casting, which reduces the deformation of the casting.

Low coefficient of thermal expansion

Can be comparable to the zircon sand.

Ensures fewer or no casting defects such as veining and deformation.

Low gas evolution and high permeability

Can reduce defects, increase overall yield of casting and lower the cost of casting materials.

Low bulk density

The bulk density is 1.79-1.87/cm3, lower than the chromite sand of 2.5-2.9/cm3.The sand core is easy to move with light weight, and also can reduce the usage amount of sand.

1.5 Application of ceramsite sand

ceramic foundry sand is widely used in foundry technique like resin-bonded sand, sodium silicate sand, and clay- bonded sand for sand core and casting mould making.

ceramic foundry sand replace chromite sand and widely used in sand core making like jacket core, oil duct core, tappet core of engine.

ceramic foundry sand

replace chromite sand for steel casting facing sand and sub-layer of molding sand (backing sand).

ceramic foundry sand is widely used as dry sand and sand box for EPC process and V method of casting processes.

ceramic foundry sand is widely used as the main raw materials of advanced refractory products (Ladle drainage sand,gravity casting material, casting coating, etc.).

Ceramsite sand is widely used as cleaning sand for copper and aluminum alloy castings.

Package: 25kg pvc bag and 1mt big bag

Shipping: by sea way or air way

Top quanlity ceramic foundry sand product

Completely size range

Professional before-sale assistantance

Perfection after-sale services

In-time transport support

Safe and customized package services

ZhengZhou Haixu Abrasives Co.,ltd,found up since 1999,start business with manufacturing of white fused alumina,after 17 years development,now we become an group company having 4 abrasives plant.

white fused alumina plant

brown fused alumina plant

black silicon carbide plant

green silicon carbide plant

2 holding plant

tabular alumina plant for refractory industry

ceramic foundry sand for foundry industry

Production capacity 200,000 MT/year.

Capital assets 2.5 hundred million.

More than 2000 staffs

Is your company a trading company or factory?

We are factory since 1999,and we have our indepent trading company since 2010

Could you send sample and how the cost assigned?

Princeple speaking,we offer free sample for customer,within 5kg,and the express cost on the customer’s side.

What’s your main market now?

Korea,Indonesia,Thailand,Vietnam,Saudi Arabia,etc.

How can pay for the shipping cost or some quantity purchase?

Payple,West Union,T/T,cash by source in china,etc.

How can I contact beside trademanager or email

You can contact me by chat tools and email below.

Wechat——-laperte3

QQ————1794891734

SKYPE——-young.yang36

Whatsapp—–0086-13608683192

Mobile———0086-13526810975

Zhengzhou Abrasives Factory Available Stocks

Zhengzhou Abrasives Factory Available Stocks

Reviews

There are no reviews yet.